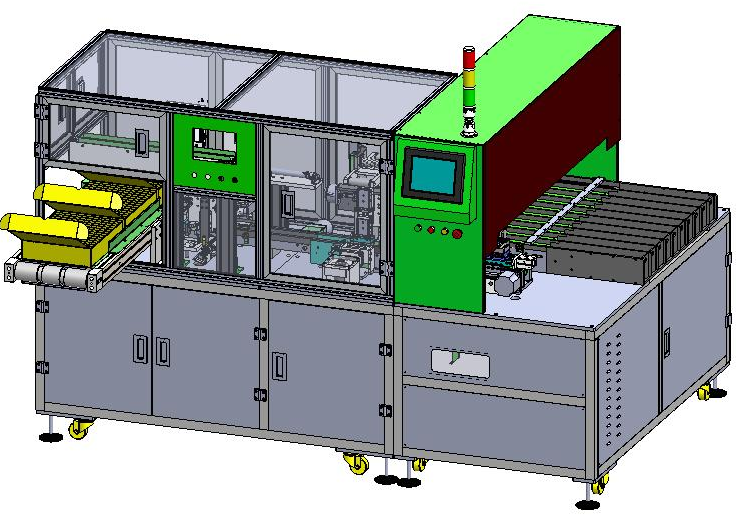

10-speed sticker sorting all-in-one machine

Customizable18650/21700/26650/32700

HTEC-1810 cylindrical 18650 battery automatic feeding and labeling sorter is a kind of testing and sorting equipment for cylindrical batteries. It is equipped with a high-precision automatic testing system for internal resistance and voltage. The equipment accurately sends the batteries to the designated gear according to the internal resistance and voltage values set in computer software, and the system can realize 10-level sorting. The overall design efficiency of this equipment is about 5000 batteries per hour, and the structural design is simple and generous, and the performance is stable. In the market, so far, it is a kind of integrated equipment with high cost performance, with automatic feeding mechanism. Typical users are Minmei, Jin Qilin, Guardian, etc.

Basic parameter

1. working voltage: AC 220v 10%/50hz, power rate: ≤ 3.5kw.

2. working gas source: 0.5~0.8 Mpa

3. Overall dimensions: 2500 (length) √ó2250 (width) √ó1580 (height) mm.

4. Each with three-color alarm lights and LED lighting.

5. Internal resistance meter: Kaya Hioki 3562 (optional)

6. Technical parameters of voltage measurement Voltage measurement resolution: 0.1mV Battery measuring instrument Voltage range: 19.9999V Accuracy: 0.01% R.D. 0.3% F.S.7. Technical parameters of internal resistance measurement Resolution: 0.1 mΩ Battery measuring instrument Resistance range: 310.00 mΩ/ 3.1000Ω Accuracy: 0.5%.

8. Working pressure: 4.8-6.0 kPa.

9. Grading: 10 grades (free allocation of qualified grades and NG grades)

10. Comprehensive efficiency: about 5,000 capsules/hour.

11. Data: Data can be saved, viewed and copied for analysis.

12. Equipment weight: 550KG.

13. Optional automatic feeding mechanism is efficient and does not damage batteries. Panasonic PLC motor sensor ensures stability, and the average calculation data has high accuracy. There is no worry about sorting error in the same industry, and the 3562 accuracy is fully exerted.