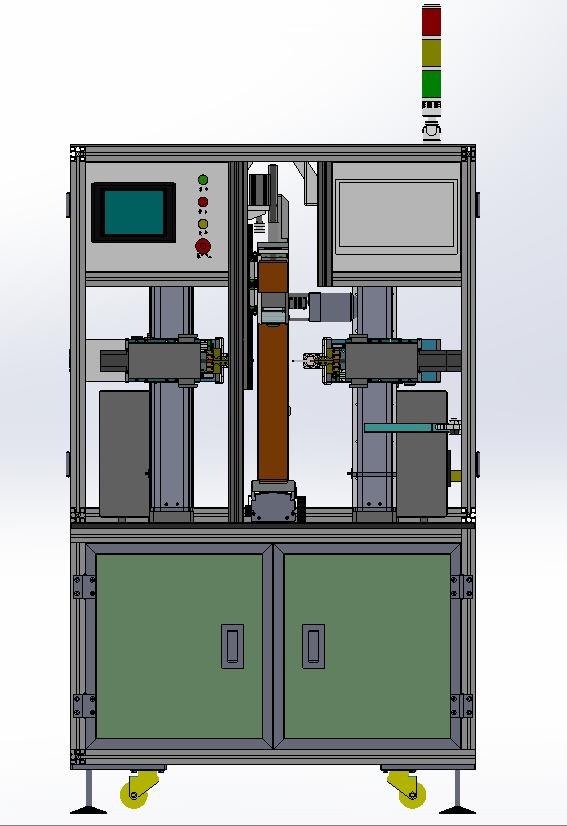

HTE-700 7-axis double-sided automatic spot welding machine

1. power supply: single-phase 220V/50HzÔºõ; (16A connector)

2: Power: 5000 W;

3. Air source: 0.5 ÔΩû0.8Mpa dry air source;

4. Equipment weight: 380kg;

5: Overall dimension: 1300 * * 1400 mm * 1800

6: Y axis stroke: 700mmÔºõ Z axis stroke: 600 mm; X axis 100mm, rotation angle 180

7: X, Y and Z analytical accuracy: 0.05mmÔºõ;

8. Spot welding pressure: 1.5-5.0 kg;

9: Effective spot welding speed: 3500 cells/h;

10. The feeding and discharging system can be advanced and discharged, and the automatic in-and-out function can be selected to facilitate the development of the production line to the fully automatic modular direction.

11. The spot welding head adopts Taiwan Province Shangyin precision slider, which is five times longer than that of the bearing head, and the pressure is more stable. The head has the rotating function, and it has the ability to weld nickel sheets with special groove direction and prevent pure nickel from sticking.

12 it has the function of breakpoint connection and one-key repair welding, and the whole column programming operation is simple.

13. Automatic compensation for copper needle wear, welding current monitoring, voltage feedback compensation current, abnormal record alarm.

14. The electrode adopts high-speed air-cooling heat dissipation instead of water-cooling complex design to solve the problem that long-time welding and high temperature affect the output stability;

15. The standard 6000A or 10000A transistor power supply produced by Haituo replaces Miaji power supply, which reduces the investment cost.

16. The welding machine has automatic recognition of welding front and back, and the welding fixture position detection alarm.

17. The machine head can be horizontal or horizontal, and various welding paths such as horizontal, vertical and M-shaped routes can be programmed.

18. 99 groups of different production programs can be saved, which is convenient for subsequent production calls;

19. Optional upper computer can monitor welding temperature, time and current, and connect MES system.