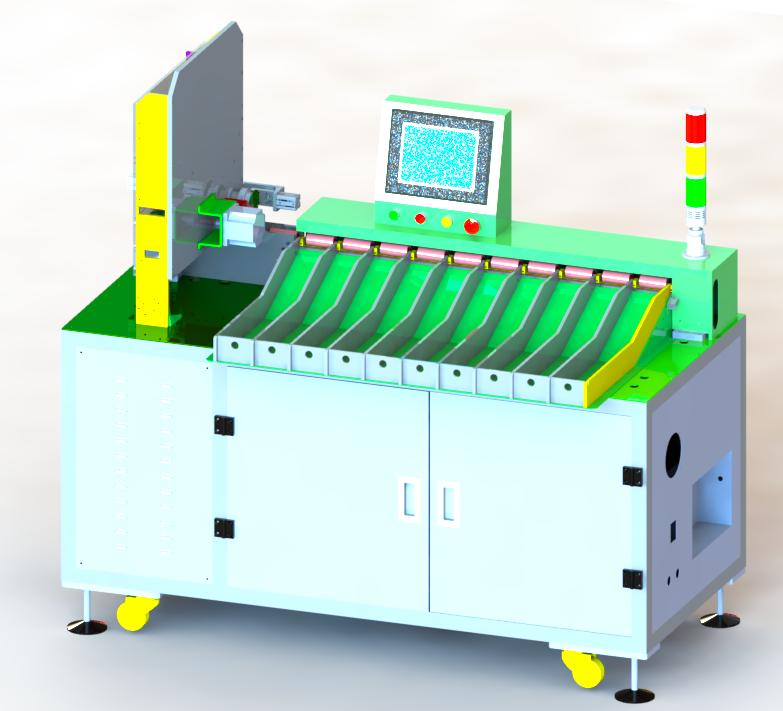

10-gear battery universal sorter (there are also 15-gear and 20-gear models)

HTEC—4000 is universal 18650/21700/26650/32700, For other models, please ask the manufacturer for information.

1. The maximum sorting gear range is 9 OK+1 NG gear.

2. Matching of various instruments: made in China & Kaya Hioki 3561.

3. The feeding trough is inclined to facilitate operation;

4. The test needle adopts 8-wire mode to improve the test accuracy;

5. Support the local storage function of test data;

6. Support the calculation of the average value of 100PCS battery parameters and the setting of quick sorting gear;

7. The equipment is equipped with intelligent self-fault judgment function to prevent the test needle from affecting the detection accuracy;

8. The automatic product program number corresponds to the product program number, which can realize automatic switching and store multiple groups of program data;

9. The call of parameters has a simple programming and easy-to-operate interface with self-learning function. Users can get a little training.

10. In operation, one only needs to take the discharge core. Everything else runs automatically, so there is no need to keep pressing the button. Greatly improve the work efficiency of workers and reduce the operation of the machine.

11. Touch screen with display to collect and display parameters and abnormal solder joint identification on the display screen in real time; It can read, write and save parameters, and automatically generate a record table for the data of each battery cell, which is saved by this machine;

12. Efficiency evaluation:It takes 0.9 seconds to test one battery cell at a time; It can sort about 65 batteries per minute.

13. Overall average time productivity of equipment: 95%

14. It can be integrated with the sticker machine into an all-in-one machine to save labor.