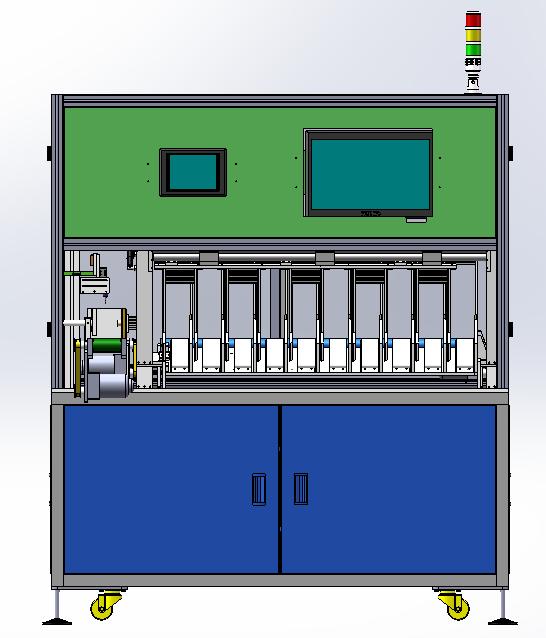

There is also a 6-speed aluminum shell battery separator.

The aluminum shell battery separator is modular in design, with optional functions: automatic feeding (robot), plasma cleaning, laser cleaning of polar column, code scanning, testing, code spraying, label printing, receiving buffer or robot receiving and docking stacker, etc., which can be matched at will to meet the needs of battery factory and PACK customers. According to the internal resistance and voltage set on the computer software, the equipment accurately sends the battery to the designated gear, and the system can realize 10-level sorting (1 test station, 2-10 sorting grades). The overall design efficiency of this equipment is up to 10PPM per hour, about 600 batteries, which is actually determined according to the function collocation and the way of material supply, and the structural design is simple and generous, and the performance is stable.

Basic parameter

1. working voltage: AC 220v 10%/50hz, power rate: ≤ 3.5.0kw.

2. working gas source: 0.5~0.8 Mpa

3. Overall dimensions: 1800 (length) √ó1600 (width) √ó1700 (height) mm.

4. With three-color alarm lights and LED lighting.

5. Internal resistance meter: Kaya Hioki 3561 (optional).

6. Applicable battery cell size: 100-300mm long, 20-85mm thick and 70-300mm high;

8. Working pressure: 4.8-6.0 kPa.

9. Grading: 10 grades (free allocation of qualified grades and NG grades)

10. Comprehensive efficiency: about 600 PCs/hour (size)

11. Data: Data can be saved, viewed and copied for analysis.

12. Equipment weight: about 380KG.

13. The core components of the large factory are guaranteed to be stable, and the average calculation data is of high accuracy, so there is no worry about the sorting error in the same industry, and the accuracy of the internal resistance meter 3561 is fully exerted, and there will be no false measurement.